Thanks to its small volumes (from 0,5l to 2,5l), the UMSK5 Stephan® is ideal for the production of small quantities for laboratory testing or for small productions. This machine has a vacuum unit, direct steam injection and a double jacket for indirect heating and cooling.

The installation is complete : frequency control for main motor, scraper gear motor, temperature feeler...the free programmable control and its touch panel allow to manage the vacuum level, the temperature, the agitating times...This machine perfectly suits to a high number of various formulations. The correct supervision of the process with a pc connection allows records and a fast and simple analysis of the data.

The installation is compact, easy handling, stainless steel chassis with rollers, easy cleaning and sterilizing by steam injection. The bowl directly flanged at bearing shield is easily dismantling for the cleaning and the weighing of used ingredients.

The developed products are easily transposable on our higher capacity range of machines (up to 1000l of product). You have a constant quality of product and feasible on a higher scale.

Products

- Mayonnaise

- Ketchup

- Dressings

- Dips

- Baby food

- Bloc cheese

- Ready meals

- Confectionery

- Marzipan

- Dispersions

- Spreadable cheese

- Processed cheese

- Emulsions

- Chocolate

- Pastry

- Pharmacy

- Cosmetics

- Surimi

Description of the machine

Bowl size : 5 liters

Capacity : From 0,5 to 3 liters max

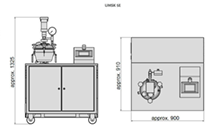

Dimensions : Length 950 x Widht 900 x Height 1300 mm

Weight : 190 kg

Working process : 110°C max

Working pressure : 0,8 bar max

Parts in contact with the product : Stainless steel V2A

Machine chassis : Stainless steel V2A

Drive :

Mounted in the machine chassis with direct drive of knife shaft

Bowl receiver with bayonet fixing

Speed : From 300 to 3000 rpm

Power : 0,75 kW

Operating voltage : 220 V , 50 Hz

Control voltage : 24 V

Power requirement : 3 kW

Electronic brake : For main motor

Emergency button

Stainless steel bowl with double jacket - water and steam -, Manually removable for the

emptying of the product. Direct steam injection.

Stainless steel cover with hinge.

Stainless steel knife shaft plugged and fixed at knife shaft with 2 knives.

Stainless steel mixing arm.

Thermical protections.

Free programmable control Simatic S7 and operating unit TP 171 for adjusting time,

temperature and rotation speed

Steam regulator, steam delivery station.

Various tools : wave-cut knives, angle-bent knives, mixing insert...

Emulsions, suspensions, sauces, soups, ingredients, ready meals, melted cheese, baby food, creams,...

Dimensions of the machine

For different volumes of production !

Please see our range of other Stephan® Universal Machines

Do not hesitate to contact us if you wish to test our machines or to schedule a demonstration on our machines in Lognes (France).