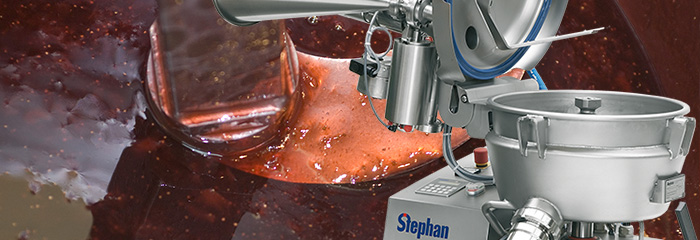

The Stephan UMSK 24 E is employed if a single machine is required to execute reliably and quickly a wide range of processing functions, such as cutting, fine cutting, mixing, stirring, kneading, making purees and emulsifying, working under vacuum as well as indirect heating/cooling and direct heating.

It is ideal for use in all fields of food processing, e.g. for the production of meat and sausages, convenience food, confectionery and dairy products in particular processed cheese.

The product contact parts of bowl and cover are made of 1.4301 or similar (V2A).

The surface is bead blasted. The bowl is designed with a double jacket for indirect heating/cooling as well as steam injection valves for direct heating of the bowl content mounted in the bottom of the bowl. By this direct steam injection the product can be heated up to 127 °C. The cover is equipped with dosing connection piece DN 32 with pneumatically operated valve, a sight glass and lamp as well as a vacuum unit. The support is made of stainless steel. The working tools are also made of stainless steel and are consisting of a knife shaft and two wave-cut knives as well as a mixing baffle with direct drive. The machine is equipped with a discharge connection DN 65 as well as a tilting device for easy product discharge. The machine is controlled by soft touch panel 3011. The readout appears in 2 lines in an illuminated LCD display. The operated keys are illuminated as well. A timer and temperature indication are included.

The main motor is equipped with a frequency converter.

Advantages :

- Energy efficient

- Short batch times

- Reduced manual work

- Direct steam injection

- Ideal for laboratory use

- Frequency controlled motor

... Do not he sitate to call us, we would be pleased to help you!

Products

- Mayonnaise

- Ketchup

- Dressings

- Dips

- Baby food

- Bloc cheese

- Ready meals

- Confectionery

- Marzipan

- Dispersions

- Spreadable cheese

- Processed cheese

- Emulsions

- Chocolate

- Pastry

- Pharmacy

- Cosmetics

- Surimi

Description of the machine

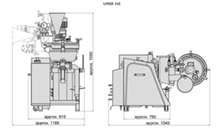

Bowl content/batch size : 30/18 max.. env. en litres

Net weight of the machine : 270 Kg

Max. permissible operating temperature - bowl : 127 (260) °C (°F)

Max. permissible operating excess pressure - bowl : 1.5 bar (PSI)

Required/max. amount of steam - direct steam injection : 28 / 75 kg/h

Max. required amount of steam - double jacket : Depending on product

Required steam pressure : 6-8 (85-114) Bar (PSI)

Required amount of water - water dosing : 15-25 l/min.

Required amount of water - vacuum pump : 2 l/min.

Compressed air : 6-8 (85-114) bar (PSI)

Operating voltage : 400 (50) V (Hz)

Control voltage : 24 V

Fuse protection 400 V/220 V : 32 A time-lag fuse

Motor with frequency converter n = 300-3000 U/min : 7.5 kW

Bowl/cover: stainless steel bead blasted

Housing/support stainless steel bead blasted

Knife shaft stainless steel, complete, without knives

Steam preparation station/steam cleaner

Set with 2 knives

Three-phases-autotransformer for 200-208-220-230 V/50…60 Hz

Discharge valve DN 65

Dosing funnel 6 l for existing connection piece DN 32

Vacuum pump (water)

Water dosing unit

Steam preparation station/steam cleaner

Grinding, mixing, cutting, kneading, émulsifying…

Dimensions of the machine

For different volumes of production !

Please see our range of other Stephan® Universal Machines

Do not hesitate to contact us if you wish to test our machines or to schedule a demonstration on our machines in Lognes (France).