Successfully used in the Food Industry

The Stephan® Combicut TC System is a multifunctional machine. It is in use successfully for a wide range of applications in the food industry.

Besides cutting, mixing and dispersing, heating and cooling can be done in the same system. The integrated vacuum system avoids oxidation and ensures a high product quality.

Advantages :

- Short batch times

- Homogeneous mixing

- Efficient cutting

- Constant specific weight

- Optimal powder dispersing

- Oxidation is avoided

- Stable emulsions

- Constant product quality

- Gentle as well as effective heating

... SeveralProcess Steps in one Machine!

Design of the Combicut TC System

The Stephan® Combicut TC combines several process steps in one machine. These are cutting, mixing, dispersing, heating, cooling, deaerating and emulsifying.

The horizontally placed mixing drum in the basis of the machine. A set of cutting and emulsifying knives is driven through the back plane by the main motor, whereas the mixing arm with scraper is activated by a motor through the front cover. The machine is charged by a slide and / or pipe connections. Discharging is done via a slide or a bottom seat valve. The Stephan® Combicut TC can be equipped with direct steam injection nozzles and / or a jacketed drum.

It can be completed by powder hoppers, liquid vessels, liquid metering systems, a lifting / tilting device, a Stephan® Microcut and a discharge wagon.

Products

- Mayonnaise

- Ketchup

- Horseradish

- Sauces

- Dressings

- Liver pate

- Surimi

- Marzipan

- Processed cheese

- Fresh cheese preparations

Applications and process steps

Mayonnaise, ketchup, horseradish, sauces, dressings

Processed cheese, fresh cheese preparations

Baby food

Surimi, liver pate

Dough preparation (TK)

Marzipan

Cutting, mixing, dispersing, emulsifying, direct + indirect heating, deaerating, cooling

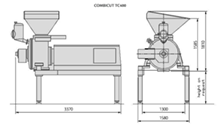

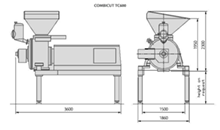

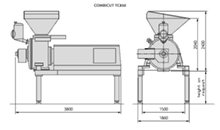

Dimensions of the machine TC 400 - 600 - 850

Do not hesitate to contact us if you wish to test our machines or to schedule a demonstration on our machines in Lognes (France).