The Microcut® MCH 20K is the ideal solution for grinding fresh and frozen vegetables, granules, fruits... This machine can also change dry biscuits and wafles residus into dry powder with an output from 400 to 1200 kg per hour depending on the start product and on the end product fineness wished.

The grinding operation means a low increasing of temperature which depends on the product and the degree of wished fineness. Generally speaking, this rise is around 5°C and therefore do not bring about separation of ingredients such as fat. The grinded material can be directly driven to the production.

The Stephan® Microcut is easy using and polyvalent. Each product is grinded by an helicoidal cutting system up to the wished degree of fineness. The combination of the feeding spiral speed and the Stephan ® cutting system insure to have a constant quality of end products, whatever the product and fineness firstly are such as pastes, masses or granules.

Thanks to a robust and functional design and also an ideal stainless steel technic, the Stephan Microcut® MCH 20K do not need any setting or maintenance, excepted for the used parts.

Products

- Biscuits rework

- Dried Vegetables

- Dried fruits

Description of the machine

Loading : Stainless steel funnel with hinge

Discharging : Outlet at cutting housing - standard height 450 mm

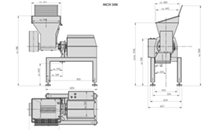

Dimensions : Lenght 1360 x Width 660 x Height 1250 mm

Weight : 260 kg

Parts in contact with the product : Stainless steel V2A

Machine housing : Stainless steel V2A

Drive :

Directly flanged at bearing shield

with direct drive of working tools

Speed : 3000 rpm

Power : 15 kW

Operation voltage : 400 V , 50 Hz

Control voltage : 110 V

Power requiement : 12 kW / 32 A curve D

Gear motor : Flanged at funnel with direct drive of feeding spiral (dismanting without tools)

Emergency button

Cutting Head

Feeding disc with feeding spiral

Slanted tooth cutting ring from 0,05 to 3 mm

Output from 300 to 1000 kg p/hour depending on product

Load part contactor control with starting-step and heater mounted in the machine housing.

Control via push buttons

Pre-cutting system, many tools,...

Electical safety lock at cutting housing/swivelling funnel

Mechanical safety lock at outlet

Safety rod mounted in the upper funnel part

Fresh, frozen, vegetables, granules, dry and filled biscuits...

Dimensions of the machine

For different volumes of production !

Please see our range of other Stephan® Mirocut

Do not hesitate to contact us if you wish to test our machines or to schedule a demonstration on our machines in Lognes (France).