Stephan®, stands for more than 58 years of experience in manufacturing plants and machines. In particular the Stephan®

Universal Machines have always impressed as flexible processunits.

The Stephan® Universal Machines handle almost all the tasks involved in the production of processed cheese, convenience products and confectionary: from mixing and chopping, emulsifying and vacuum deaeration to heating and cooling.

The Stephan®Universal Machines all share one important characteristic: versatility.

These multi-functional batch machines, all of which following the unique Stephan® principle, can be relied upon to carry out the entire process with all production steps.

Product

- Mayonnaise

- Ketchup

- Dressings

- Dips

- Baby food

- Ready meals

- Confectionery

- Marzipan

- Surimi

- Dispersions

- Emulsion

- Chocolate

- Pastry

- Pharmacy

- Cosmetics

Description of the machine

Bowl size : 70 liters

Capacity : Env. 55 liters

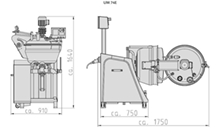

Dimensions : Lenght 1200 x Width 1100 x Height 1850 mm

Weight : 300 kg

Max. permissible operating temperature - bowl : 95°C maximum

Max. permissible operating excess pressure - bowl : 0 bar

Motor with frequency converter n = 300-3000 rpm : 11 kW

Operating voltage : 400 v

Frequency : 50 Hz

Control voltage : 24 V

Fuse protection 400 V/220 V : 32 / 63 A

Bowl stainless steel bead blasted 1.4404

Housing/support stainless steel bead blasted 1.4301

Mixing arm stainless steel

Vacuum unit

Double jacket heating / cooling

Water dosing unit

Discharge valve

Temperature feeler

Butter preparations

Fresh cheese preparations

Dressings, dips

Confectionery fillings, Ganache

Mayonnaise

Hummus

Meat emulsions

Liver paté

Dimensions of the machine

For different volumes of production !

Please see our range of other Stephan® Universal Machines

Do not hesitate to contact us if you wish to test our machines or to schedule a demonstration on our machines in Lognes (France).