All those involved in food processing will be aware of the superiority of Stephan® machines. In particular, the Universal Machines have always impressed the experts. The machine’s uncompromising top-class performance exceeds the highest demands of customers who really know what the market has to offer. Stephan® stands for more than 50 years of experience in manufacturing plants and machines.

The Stephan® Universal Machines handle almost all the tasks involved in the production of processed cheese, convenience products and confectionary: from mixing and chopping, emulsifying and vacuum deaeration to heating and cooling. The Stephan® Universal Machines all share one important characteristic: versatility. These multi-functional batch machines, all of which following the unique Stephan® principle, can be relied upon to carry out the entire process with all production steps.

Advantages :

- Easy filling and emptying

- Effective cutting and mixing

- Indirect and/or direct heating

- High hourly output with short batch times

- Easy to operate

- Easy to clean

- Compact design

... Here is flexibility at home!

Pour d’autres volumes de production, nous vous proposons toute une gamme de Machines Universelles

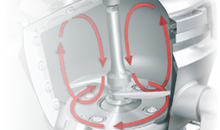

The STEPHAN® Universal Machines are filled either via the open cover or via dosing valves. All processing steps are performed according to the proven Stephan® principle: Each process is achieved in one machine (all-in-one), the power of the main motor is transferred directly to the knives - without gear! The rotating knives, reverse-acting scraper arm together with the interaction of the special bowl-geometry achieve optimum processing of the product.

Stephan® Universal Machines double up for many jobs. For example, if you want to produce processed cheese. Stephan® UM processes pieces of butter and cheese up to a size of 2 kg without any problems. You don’t need an additional grinder.

Also gentle treatment occurs when heating and cooling. The product may be heated indirectly with steam via a double jacket or fast and environmentally friendly by injecting direct steam via steam nozzles in the vessel bottom. But, don’t forget you can use the cylinder jacket also to cool the product with cooling water.

The discharge of the product is made either via a discharge valve or by tilting the bowl through 90°.

Product

- Mayonnaise

- Ketchup

- Dressings

- Dips

- Baby food

- Bloc cheese

- Ready meals

- Confectionery

- Marzipan

- Dispersions

- Spreadable cheese

- Processed cheese

- Emulsions

- Chocolate

- Pastry

- Pharmacy

- Cosmetics

- Surimi

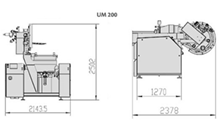

Dimensions of the machine

For different volumes of production !

Please see our range of other Stephan® Universal Machines

See the processes

Cutting, mixing, emulsifying, vacuum, direct heating, heating and cooling (indirect)

All kinds of processed cheese, ketchup, mayonnaise, ready meals, soups, sauces, dips, marzipan, alond paste, confectionery filling

Do not hesitate to contact us if you wish to test our machines or to schedule a demonstration on our machines in Lognes (France).