Universal machines type UM 130 are useful for cutting, mixing, kneading, emulsifying ; only one Stephan® machine for several processes. It means one investissment, an optimal using of the machine and a flexible planning of production. Thanks to its different executions and full additionnal equipments, the Stephan® machine is perfectly fitting to the needs of all branches..

The Stephan® universal machines are easy handling. They are the result of a long experience and a continous technical development. With a speed rotation of 750, 1500 and 3000 per minute, soft, hard, stringy, viscous or dry materials are intensively worked and changed into an homogeneous or regular product more or less thin, depending on the recipe.

A supplementary rotative movement is obtained thanks to the higher mixing arm that scraps the jacket of the bowl and the cover and comes back to the knives. Thus, all the ingredients of the recipe are spreaded and mixed homogeneously.

Times of process faster, several usings and easy handling of the Stephan® machine rationalize work processes and bring to a better profitability.

Product

- Mayonnaise

- Ketchup

- Dressings

- Dips

- Baby food

- Ready meals

- Confectionery

- Marzipan

- Surimi

- Dispersions

- Emulsion

- Chocolate

- Pastry

- Pharmacy

- Cosmetics

Description of the machine

Bowl size : 130 liters

Capacity : From 35 to 100 liters max

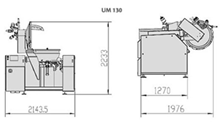

Dimensions : Length 1660 x width 1930 x Height 2100 mm

Weight : 750 kg

Working temperature : 95°C maximum

Working pressure : 0 bar

Parts in contact with the product : Stainless steel V2A

Machine chassis : Stainless steel V2A

Drive : With motor hood directly flanged at the bowl with direct drive of mixing baffle

Speed : 750 /1500, 1500 / 3000 or 750 / 1500 / 3000 rpm

Power : 10 / 17, 18,5 / 22 (reinforced) or 10 / 13 / 20 kW

Operation voltage : 400 V , 50 Hz threephase AC

Control voltage : 24 V

Power requirement : From 30 to 36 kW / 50 to 63 A curve D

Brake : Power injection

Emergency button

Stainless steel bowl on the main drive. Manually tiltable for product discharging

Stainless steel cover

Knife shaft stainless steel plugged and fixed at knife shaft with 2 narrow knives

Wide knives or wave-cut knives

Stainless steel mixing arm with scraper.

Gear motor directly flanged on cover.

Soft touch keybord 3011 for main motor on the panel control, for temperature display and for working process time by switch.

Double jacket, vacuum pump, temperature feeler, discharge valve, frequency control, free programmable control frequency control...

The machine can be delivered on a skid, with a buffer tank, a cream vessel or a discharging pump.

Chocolate interiors, ganache, delicatessen products, stuff, sauces, melted cheese, confectionery and bakery products...

Dimensions of the machine

For different volumes of production !

Please see our range of other Stephan® Universal Machines

Do not hesitate to contact us if you wish to test our machines or to schedule a demonstration on our machines in Lognes (France).