The Microcut MCH-D 150 is the fundamental basis to rationalize the food process of sausages and other foods products in salting, delicatessen and in industry under a cutter or a mixer. It is the right machine for industries which produce fine stuff, baby food, cooking steady emulsions, soups and sauces...Crude rind emulsions or transformation of meat coming from separators are not a problem.

For various processes, a simple cutting and a good mixing are necessary before entering the Microcut.

The core of the Microcut is the double level of the cutting system, directly flanged at bearing shield with direct drive of working tools. Thanks to its cutting system, the crossing of the products is very fast and the wanted fineness is obtained. The emulsion and liaison are ideal, without melting while cooking. There is no friction and the Microcut can work vacuously.

Avantageous of the Stephan® Microcut : a frank and neat cutting, without crushing, laminating or heating ; a smooth and homogeneous product without air; ability to work under vacuum. Quality and fineness of the product are constant and the operator has no setting to do.

Excepted the sealing ring of the motor, there is no need of special maintenance, easy cleaning and tools can be fastly changed. Made of stainless steel. The Stephan® Microcut is easy using and polyvalent. The fast time of process and easy using rationalize the work process and allows a better profitability. The dimensions of the machine allow it to be placed under a mixer or a cutter.

Products

- Pet food

- Skin emulsion

- Meat emulsions

- Emulsion diverses

- Sauces

- Liver pate

- Pet food

- Baby food

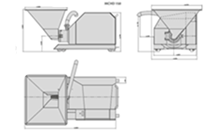

Description of the machine

Loading : Stainless steel funnel with hinge

Discharging : Removable feeding pipe DN 65

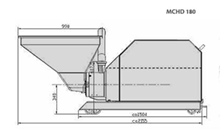

Dimensions : Lenght 1800 x Width 870 x Height 900 mm

Weight : 1150 kg

Parts in contact with the product : Stainless steel V2A

Machine housing : Stainless steel V2A

Drive :

Directly flanged at bearing shield

with direct drive of working tools

Speed : 3000 rpm

Power : 45 ou 55 kW

Operation voltage : 400 V , 50 Hz

Control voltage : 110 V

Power requiement : 45 or 55 kW / from 80 to 100 A curve D

Gear motor : Flanged at funnel with direct drive of feeding spiral (dismantling without tools)

Emergency button

2 Cutting Heads

2 Slanted teeth cutting rings from 0,2 to 10 mm for open cutting rings and from 0.20 to 1.30

for closed cutting rings

Temperature feeler

Output from 3000 to 4500 kg p/hour depending on product

Load part contactor control with starting-step and heater mounted in the machine housing

Control via push buttons

Reinforced motor, many tools, vacuum unit system

Also existing in MCH-D180 and MCH-D200

Purees, stuff , emulsions, baby food, sauces...

Dimensions of the machine

For different volumes of production !

Please see our range of other Stephan® Mirocut

Do not hesitate to contact us if you wish to test our machines or to schedule a demonstration on our machines in Lognes (France).