Constant product quality due to precise process control

Continuous processing enables high production capacities at high precision. The Stephan® Conti-Lines are based on a modular concept. Customer specific solutions are designed by combining these modules according the project requirements.

Due to the high degree of automation the operating effort is minimized. A precise process control system ensures a constant product quality.

Advantages :

- Precise process monitoring

- High degree of automation

- Excellent CIP cleanability

- Constant product quality

- Customizes Solutions

- Minimized manpower

- Turn Key Solutions

- Safe production

... Individual Turn-Key Solutions!

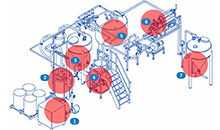

Design of the continuous processing line®

As the Stephan® Conti-Lines are based on a modular system, they can be combined according to the customer requirements.

In the basic system liquids are metered mass proportional and mixed continuously. The Stephan Microcut® can be integrated for inline homogenising.

The product can be heated indirectly by heat exchangers or indirectly by the Stephan direct steam injection techniques. The systems are CIP-cleanable.

Example for compact Stephan toato ketchup line :

Produits

- Mayonnaise

- Ketchup

- Salad sauces

- Baby food

- Mixed products

- Sauces

- Cream soups

- Soups

- Vegetable puree

- Veloute

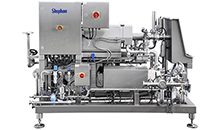

Key component: Stephan® Continuous Cooker

The Stephan® Continuous Cooker consists of a high shear mixer with direct steam injection nozzles. The product is heated instantly by steam condensation.

Burn-on is avoided. The short heating time is colour and flavour protecting.

Advantages :

- Processing of particulates

- Flavour saving process

- Colour saving process

- Minimized residuals

- Avoiding of burn-on

- Instant heating

Features :

- Direct steam injection nozzles

- Emulsifying or mixing tools

- Controlled throughput

- Controlled temperature

- Variable rotor speed

- Heating up to 96 °C

- Short heating times

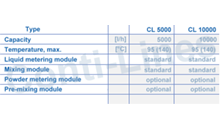

Stephan® Conti-Line Mayonnaise

Mayonnaise basically consists of an aqueous phase and an oil phase.

Egg yolk or egg yolk powder is used as an emulsifier.

Continuous processing lines for mayonnaise include mass proportional metering of the liquid, pre-mixing and dispersing of the powders and emulsifying.

Example : Low Fat Mayonnaise :

Description of the machine

Drum discharging module

Data management system

Indirect Heating module

Direct Heating module

Emulsifying module

Cooling module

Dimensions of the machine

Do not hesitate to contact us if you wish to test our machines or to schedule a demonstration on our machines in Lognes (France).